| N |

document

name |

language |

comment |

0. |

Cooperation

and Partnership |

|

|

|

| |

We are looking

for new serious partners. |

|

|

general presentation

for partners |

| |

Agent - vacancy

description |

|

|

|

| |

Where it can

be useful |

en |

|

|

| |

Why We are

best. |

|

|

|

| |

1. |

Work

with customers. |

|

|

|

| |

Work with

customers - algorithm, documentation and support. |

|

|

|

| |

Quick initial

evaluation of investment efficiency of TRGA technology for boiler |

|

|

Quick price

|

| |

Short questionnaire

for boiler or owens. |

|

|

|

| |

Full questionnaire

for boiler or owens. |

|

|

|

| |

Questionnaire

for diesel generator power plants. |

|

|

|

| |

Questionnaire

for ships. |

|

rus |

|

| |

Questionnaire

for the production of winter diesel fuel. |

|

|

|

| |

Questionnaire

for mixing various multicomponent mixtures and suspensions. |

|

|

|

| |

Certificates

and guarantees. |

|

rus |

|

| |

How long fuel

homogenizer TRGA works

in real industrial conditionals ? |

|

|

from 2 up

tu 6 years |

| |

How much solids

passes through the fuel homogenizer TRGA for 1 year - wagon. |

|

|

|

| |

How long black

oil retain its new properties after homogenizing via fuel homogenizer

TRGA ? |

|

|

6 years |

| |

Free test

of our equipment. Motives, Factors, Ideas ... (only

from the manufacturer)

|

|

|

We agree to

a partly paid test (PPT)... |

| |

2. |

Boilers

and ovens. |

|

|

|

| |

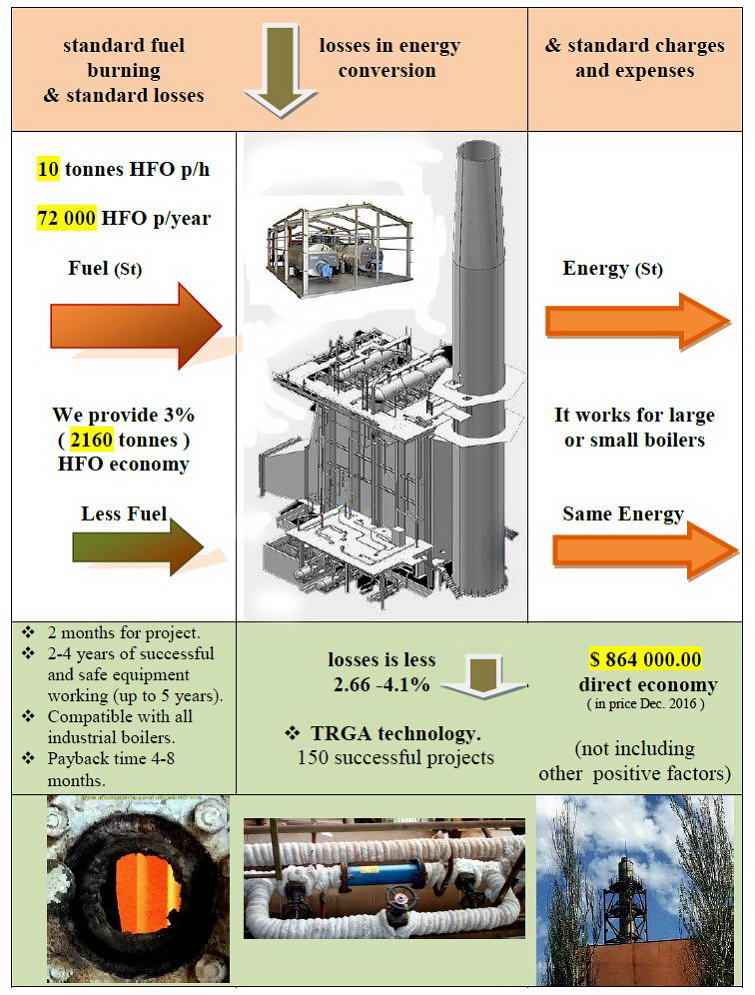

Short

offer for fuel-saving TRGA system for industrial boiler

and furnaces of any design. |

|

|

shortest document

for busy managers |

| |

An example

of a typical offers for fuel-saving TRGA system

for the industrial boiler. Three connected parts -

declaration and conditions for managers, images and effects for

technicians and detailed explanation for experts. |

|

|

different

documents from the specifics of different mentality. for somebody

it is possible to tell briefly, some other required dissertation. |

| |

Savings on

fuel oil boiler, without adding water, additives. Internet version.

Official test results. |

|

|

Fuel economy

4.1%

or 2,952 tons per year. |

| |

Savings on

fuel oil boiler, without adding water, additives. Internet version.

Official test results. |

|

|

Fuel economy

4.1%

or 2,952 tons per year. |

| |

Testing TRGA

fuel homogenizer in industrial boiler with automation and control

systems. |

|

|

Fuel economy

3.7 %

or 3200 Euros per month. |

| |

TRGA fuel

homogenizer. |

|

|

|

| |

Sremska Mitrovica,

Serbija, Municipal enterprise "Pannonian power chains,"

12 months of exploitation, 2 industrial tests. Nikola Tesla's laboratary

report. 6 months of operation.

Report fuel economy.

Report ecology.

|

|

|

Fuel economy

2.6%, reduced NOx, SO2, CO. |

| |

Ukraine, Mariupol

trading port. Works till today, report. Results - successful combustion

recycle watered fuel mixture with a water content of 20%. and watered

oil sludge in the port. Presented at the international conference. |

|

|

|

| |

One of the

feedback from the client - the result of work TRGA homogenizer.

Ukraine.

(after 4 months of operation)

|

|

|

burning mazut

with 20% water content and high content mechanical impurity |

| |

Fuel economy

and burning flooded, low-quality fuel on the asphalt furnace with

simultaneous production of asphalt. |

|

|

no info about

fuel economy, but work and no smoking |

| |

Using a fuel

homogenizer TRGA for best burning and saving slurry heavy

fuel oil. Reducing specific fuel consumption. short test. |

|

|

Fuel economy

3.73 % or 1,208 tons per year. |

| |

Using a fuel

homogenizer TRGA for best burning and saving slurry heavy

fuel oil. Reducing specific fuel consumption. long test. |

|

|

Fuel economy

4.5 % or 1,458 tons per year. |

| |

Proposal for

the chief technologist of oil refinery (reduction in specific

consumption and clogging of heat exchangers). |

|

|

overview document

with a minimum fuel economy figures |

| |

Clean

heat exchanger in the boiler before and after ...

usin our units and systems |

en |

rus |

for

customers only |

| |

Model

contract for the supply of equipment, warranty and service |

en |

rus |

for customers

only |

| |

Reduction

on soot and unburned asphaltenes on oil

fired boiler's heat exchangers. |

|

|

|

| |

Using a homogenizer

TRGA for small boiler, 6 months return, 3 and more

years of work. |

|

|

|

| |

The research

work of TRANSNEFTEMASH, Russia, on the use of a

homogenizer of the TRGA series to save boiler fuel. ( " -5%

") |

|

|

Full doc for customer only |

| |

3. |

Tank

farms. |

|

|

|

| |

Saving black

oil, recycle waste oil residues and oiled condensate water in the

ports and tank farms. |

|

|

|

| |

Oil sludge

treatment and incineration using a homogenizer TRGA. |

|

|

|

| |

Processing

of heavy tar and heavy viscous petroleum oils or high viscosity

fuel oil manual

|

|

rus |

for customers

only |

| |

Utilization

of oil sludge from open storage. Scheme and instruction. |

|

rus |

for customers

only |

| |

Universal

design for oil terminals and ports for the disposal of residues

of fuel and oily water |

|

|

|

| |

How to reduce

losses in transit crude oil tanks. |

|

|

|

| |

Reduce losses

in transit crude oil tanks - tech. offer. |

en |

rus |

for customers

only |

| |

The results

of processing medium-viscous crude oil on a TRGA device (non-reagent

natural oil viscosity reduction) Moscow, 2018 ( "

-21% ") |

en |

rus |

for customers

only |

| |

How

to slow down the process of settling crude oil / HFO and amount

of sludge ? |

|

|

|

| |

4. |

Ship

fuel. |

|

|

|

| |

Description

of the pilot project. |

|

|

|

| |

PSSF technology

presentation. |

|

|

|

| |

TYPE APPROVAL

Certificate IACS. |

|

|

|

| |

PSSF technology

certification. |

|

rus |

|

| |

The official

report laboratory of group INA, Zagreb, Croatia on the nature of

changes in the ship's fuel before and after treatment. |

|

|

|

| |

The official

conclusion of the pilot project - installation of PSSF on the ship. |

|

|

|

| |

Modernization

of the system for the preparation of fuel for the ship's boiler

(tanker). |

|

|

|

| |

Ship fuel

IFO-180, qualitative changes after processing the fuel homogenizer

TRGA. Analysis from refineries in Croatia. |

|

rus |

|

| |

Ship fuel

IFO-180, qualitative changes after processing the fuel homogenizer

TRGA. Analysis from refineries in Slovenia. |

|

rus |

|

| |

Automotive

diesel fuel quality changes after the fuel processing homogenizer

TRGA, visually |

|

rus |

|

| |

"Hercules"

project (Greece) for heavy marine diesel engines - differences from

the our system. |

|

|

|

| |

IPCO POWER

project (Germany) for heavy marine diesel engines - differences

from the our ststem. |

|

|

|

| |

Manufacture

ship fuel using the fuel (oil) wastes. |

|

|

will be supplemented

the process of obtaining new data |

| |

Bunker fuel

Manufacture |

en |

|

|

| |

Need to use

homogenizing fuel in powership |

|

|

|

| |

5. |

Engines. |

|

|

|

| |

Decrease

in specific consumption of diesel fuel on diesel generators. |

|

|

|

| |

Estonia, Tallinn.Tehnichesky

University, tests on a special italian stand (5. KW, 4-cylinder,

hydraulic brake, measuring equipment), to investigate the specific

consumption of diesel fuel. |

|

|

Result -

power increase 10%-12% savings, and some other effects. |

|

Equipment

for the production of diesel fuel with waste motor oil. |

|

rus |

Fuel

economy 3-5%.

for customers only |

| |

Transfer industrial

generators from diesel fuel to ship fuel. Standard solution from

Alfa Laval. Lacks and alternative. |

|

|

Alfa Laval

system not only do not work in the russian HFO but also require

multiple hardware redundancy |

| |

Fuel module

for improvement (modification) of diesel fuel. |

|

|

From Hugo

Junkers systems till today |

| |

Tallin 2014

– test diesel fuel after processing by TRGA gomogenizer |

|

|

|

| |

|

|

|

|

| |

6. |

Documentation

for fuel homogenizer TRGA. |

|

|

|

|

Why

do I need a homogenizer TRGA. |

|

|

|

|

TRGA-3G-04S

INSTALLATION, OPERATION, MAINTENANCE MANUAL. |

|

|

productivity

4 cub. m. p/h - example |

| |

HYDRODYNAMIC

FUEL EMULSIFER TRGA-3G-04S PASSPORT. |

|

|

productivity

4 cub. m. p/h - example |

| |

TRGA-3G-04S

- final installation instructions |

en |

rus |

for customers

only |

| |

Brief instructions

on how to visually check the effectiveness of fuel homogenizer

TRGA. |

en |

rus |

for customers

only |

| |

Base installation

scheme for boiler and owen. |

|

|

|

| |

TRGA industrial

module full specification |

en |

|

for customers

only |

| |

TRGA laboratory

module full specification |

en |

|

for customers

only |

| |

Schemes and

methods for modernizing the fuel tanks for the intensification work

of the homogenizer. |

en |

rus |

for

customers only |

| |

Schemes for

mixing multiple components for the production of ship fuel with

productivity 70 m.c. p/h. |

en |

rus |

for

customers only |

| |

Schemes for

dewatering sludge and followed homogenization for boiler fuel production. |

en |

rus |

for

customers only |

| |

Scheme system

for producing winter diesel fuel with productivity 150 m.c. p/h. |

en |

rus |

for

customers only |

| |

Scheme system

for processing shale oil. |

en |

rus |

for customers

only |

| |

Scheme of

the test semiindustrial system for selection composition and proportions

for multi-fuel components blends. |

en |

rus |

for customers

only |

| |

7. |

Useful

photo |

|

|

|

| |

Heavy black

oil mazout M-100., standart. |

|

|

before and

after homogenization via TRGA unit |

| |

Watered heavy

black oil mazout M-100. |

|

|

before and

after homogenization via TRGA unit |

| |

Coal tar pitch,

standart and watered. |

|

|

before and

after homogenization via TRGA unit |

| |

Water-coal

fuel sample of dispersion. |

|

|

|

| |

Slurry - example,

dispersion mineral in oil |

|

|

|

| |

liquid oil

sludge from open storage.

recovery, production of boiler fuel, burning |

|

|

|

| |

8. |

Useful

films. |

|

| |

Comparative

examples burning arabian heavy fuel oill, original, after homogenization,

watered 10%. |

|

|

|

| |

Treatment

of fuel on asphalt plant. Before and after - effects are obvious. |

|

|

|

|

9. |

Other. |

|

|

|

| |

How long black

oil retain its new properties after homogenizing via fuel homogenizer

TRGA ? |

|

|

6 years |

| |

Power dissipation

inside fuel homogenizer TRGA. |

|

|

it is equal

Makarov pistol bullet caliber 9 mm = 478 Joules. |

| |

Comparison

fuel homogenizer TRGA with rotary homogenizer. |

|

|

|

| |

10. |

Offers

for cooperations. |

|

|

|

|

Systems to

save the ship's fuel. |

|

|

1. Cooperation

2. Full production |

|

Systems to

save fuel oil for boilers and furnaces. |

en |

|

1. Cooperation

2. Full production

3. Agency agreement |

|

Systems for

the utilization of liquid sludge |

en |

|

1. Cooperation

2. Full production |

|

Info for Commerce

Chamber of Commerce |

|

|

|

| |

|

|

|

|

|

|

11. |

Agriculture. |

|

|

|

| |

A typical

offer for the sugar / alcohol plants to reduce the cost of production |

|

|

|

| |

|

|

|

|

| |

12. |

Press

about us - articles and films. |

|

|

|

| |

The first

award (Ukr.) |

|

|

|

| |

The first

interview (Ukr.) |

|

|

|

| |

Customer reviews

(Ukr.) |

|

|

|

| |

Publication

in Commerce and Industry Chamber of Ukraine Journal (Ukr.) |

|

|

|

| |

Kazakhstan

Energy Journal (Kaz) |

|

|

|

| |

Nornikel factory

newspaper |

|

|

|

| |

Energy supply

News Journal (Rus.) |

|

- |

for

customers only |

| |

Energy supply

News Journal (Rus.) |

|

- |

for

customers only |

| |

Kazzinc factory

newspaper |

|

|

|

| |

Linkedin open

published |

|

|

|

| |

Movies on

YouTube |

|

|

|

| |

Promotional

video on the exhibition in Shanghai, China CIIE 2018 |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

| 13. |

Presentations

at exhibitions. |

|

|

|

| |

CIIE

2018, Exhibition in Shanghai, China. Presentations at the

national stand of Ukraine, as one of the best export technologies.

November 5-10, 2018 ( HFO economy ) |

|

rus |

|

| |

Waste

air & gas management

Kiev, Chamber of Commerce and Industry of Ukraine. November 27-28,

2018. (reduction of harmful emissions by eliminating their causes) |

|

rus |

|

| |

Low-cost projects

in the energy sector, The triple efficiency of the TRGA

fuel homogenizer, with a new fuel oil tax from the IMF. |

|

|

|

| |

|

|

|

|

| |

| 14. |

Some

related articles. |

|

|

|

| |

Two

very useful articles to study for everyone who is thinking

about buying fuel homogenizers (cavitators, etc.) - it’s written

simply for everyone. In two parts. Published at 15, 16 on

rosteplo.ru, at the request of their website and magazine. Who

can not download write - we will send in pdf. |

- |

|

|

| |

Fatally

useful fuel improvement.

85 years ago, preparing for a big war, German Luftwaffe understood

the need to maximize the bombing load and the range of the bombardier.

|

|

|

On Linkedin

( rus

) |

| |

The

real history of the creation of a TRGA homogenizer. |

|

|

|

| |

The

goal is survival. The objective need for new technical

unions between large corporations and small engineering firms. |

|

|

|