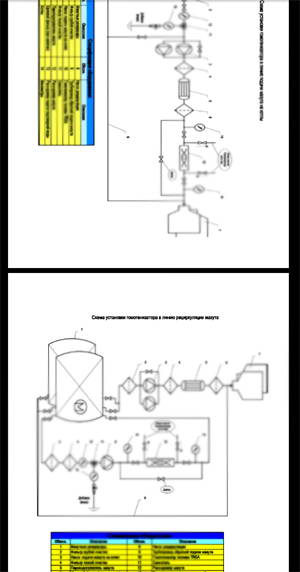

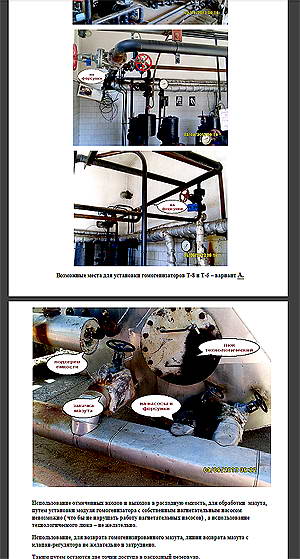

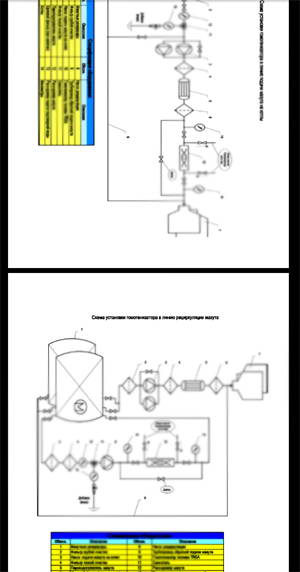

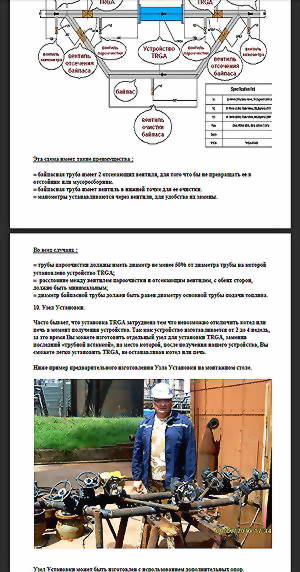

| Individuality

and typical technical solutions. In

simple cases, we use standard schemes, adapting them to the

specific customer, in difficult situations, we combine these

schemes or carry out necessary additions, but we have mounted

tech solutions more than 90

individually variants.

You can see

not only the thorough development, but also the amount of extra

work and parts that we use on-site, to reduce the overall project

cost.

Every single

object - is analyzed on the basis of the questionnaire in order

to maximize the effect and minimize the total cost. When the

coincidence of objects - the price for each remains unchanged.

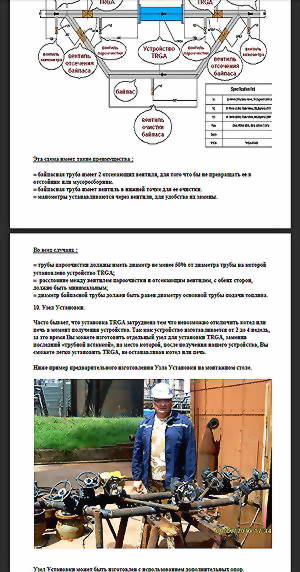

The

required productivity of the device, as well as the number of

devices are not always directly related to fuel consumption

at the boiler.

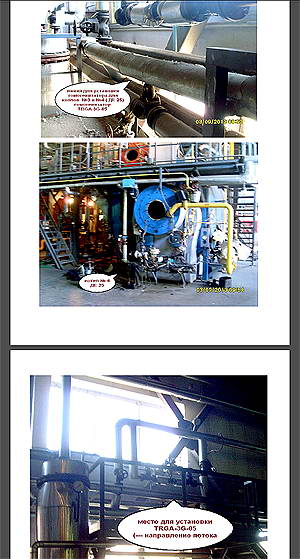

Technical reasons

(such as the presence of particular setting pressure pump) require

the installation of in fuel supply line unit same productivity

regardless of the actual consumption of fuel oil.

Conversely,

when there are multiple low-power boilers, effective technical

solution is often not install the unit in front of each boiler

separately, but installation one device for the treatment of

heavy fuel oil in the supply from tank or storage tank. So the

required productivity of the device is determined by factors

such as - the total flow rate for all the injectors, the volume

of the container for the fuel processing and the temperature

and viscosity of the fuel in the tank, as well as its geometrical

dimensions.

It is for

this reason, before analyze each

individual questionnaire is impossible to determine the full

specifications of main and auxiliary equipment, as well as the

number and types of our devices.

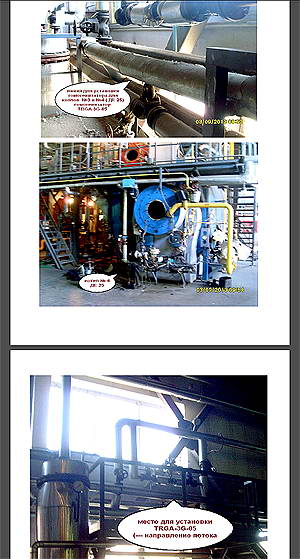

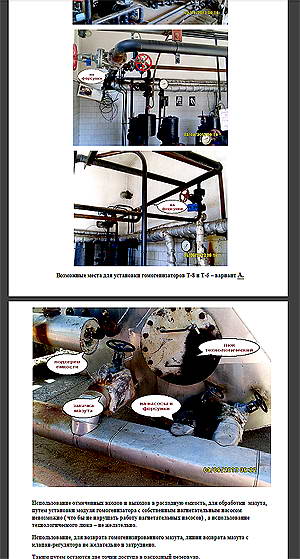

Lower

total cost of the project reached the maximum use of local staff,

local primary and auxiliary equipment - pumps, pipes,

valves, gauges, pumps, control systems, and so on.

Normal

payback time for our complete TRGA systems is not more 3-6 months.

The minimum expected life of 1.5-2 years, for

small and medium-sized boilers. Many of our devices are working

3-5 years ...

Differences. Our

devices are much cheaper than European and

American counterparts, such as ship homogenizer module made

in Germany, with a capacity of 4.5 cubic meters per hour for

up to 242 days of work, worth 26,000 euros ...

Our

devices are much more durable and more reliable counterparts,

as the U.S. and EU firms tend to use outdated design from the

USSR, which fall in the incomplete form in Europe with fantastic

promises about the effectiveness of their work. Manufacturers

of Spain and India - usually replicate the same model, so as

they have a sign - "Made in USA" or "Made in

the EU."

Our devices which are installed in the fuel line to the injectors

have no analogues in the world, on the parameters -

efficiency, durability, ability to work at high pressures and

temperatures. As well as ability to work effectively

when the volume and pressure of the flow stream changes (which

is typical for any boiler) as well as allow for efficient operation

by changes in viscosity and fractional composition of the fuel.

Our TRGA

devices are certified RTN - Russian Technical Standard,

a license to use this equipment at highly hazardous facilities

in Russia, Belarus and Kazakhstan and EU quality certificate.

|