|

our

business philosophy

|

|

our

business philosophy Construction, industrial

safety, durability, selection of individual schemes and rules of use,

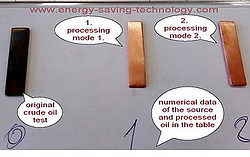

constant contact, honest guarantee. There are companies that are in the market for more than 10 years, but 10 years ago - let the old design. The reason is clear - the old grandfather - inventor and tough boss, who is used to save on everything but themselves. There are companies that are full to the market at any price and installing 2.3 of its machines, boldly write about the next upgrade. Rhetorical question remains how she will show in real life. Over the 11 years of our history modernization was carried out 4 times and one time was completely replaced by the base model. From 01.01.2007 to 21.07.2021 was sold and installed 177 units TRGA. All machines work TRGA, none returned. We have detailed reviews with pictures, at some sites visited by one year, two - take pictures, listen to the complaints and suggestions. 2. Industrial reliability. Tens of hundreds of activators and homogenizers patented. One hundred and fifty work in the laboratory, clean filtered environments only, four dozen were put into production, but have remained in history, after 3-5 units. Ukrainian market

for example, Section 3-4 major manufacturers, each of which took a significant

share, the rest just get underfoot, reprinting texts and stealing pictures.

The Russian market is the same, only the numbers a little higher, but

the experimenters ignoramuses by blood on your equipment - much higher.

In this way the actual devices that operate in real industrial conditions

on the real fuel - in each of the SNG (formed USSR) stations - can be

counted on the fingers. We do not declare

like others that TRGA work 10 or 25 years ... but some TRGA units passed

through more than 200 000 tonnes of fuel oil, and the payback period

3-6 months. And we have a right to say it - it proves

our news feed (in russian sorry) 3. Individual selection scheme and the rules of use You've seen some

of our results - www.afuelsystems.com/ru/trga/trga-mz.html

and understand that not every client gives written feedback, although

some give it after 3-6 months of work ( most importantly ). Failures were due to various reasons. Lack of money, job competition, corruption schemes, avoiding the use of fuel oil, war, mistrust, change of personnel, the greed of intermediaries, and sometimes arrogance based on nationality. Does not matter. The fact is that

in my archive of about 300 well-developed technical proposals, each

of which is based on the individual questionnaire responses and specialists.

Very few repetitions. This documentation shall be confidential, because

it describes the specific parameters of each client (hosted or not -

does not matter) because it is not published. The site shows only general

concepts - and funny to watch as they mindlessly copying others. To reduce the cost of installation, we carefully paint the installation procedure that could be most of the work yourself Finally - scheme.

Any activator or homogenizer - only a tool, without using the optimal

scheme - its effectiveness is greatly reduced. And we have more than

300 developed schemes and 157 is actually tested. 4. Constant contact. I hate the people on whom I spent my money and then they do not pick up the phone, if you have questions or concerns. And the truth is that these vendors - 90%. Proper impetus to this article from today that I brought a device with a broken panel and I, measuring on its own, called, thinking that the provider will come to me immediately and say what should be - "I'm sorry, we replace the eliminated", but alas .. . and it happens often ...All my phones, as well as phones of all my partners who works with your object - has no evening or weekend. People who pay us the money - is the person number 1. For his question, and the more his problem we have always the time and not the word "I'm busy." With the same zeal I myself and all my colleagues are our business. For us, it's a lifestyle. It is a pity that most of the vendors working on another. You know this. You

have to understand that I, according to the laws of Ukraine, have responsible

for my activity of all my assets. Please Say, have I a right to be wrong,

if my unit is mounted on boilers, each of which costs between $ 300

000? 5. Honest Warranty. Iron is iron, and from the 160 units, we replaced 5 devices. (Belarus (1), Russian

Federation (2) - not welded seam on the flanges - filtering the fuel

under pressure (our fault) - Fixed by our dealer. So you can be sure

that no one from our community will tell you - "it's your problem." That is our business philosophy. I did not give any or links here, but every word I write here can prove with documens Difficult and thankless mission Many pages on our

site devoted to the analysis or similar devices. I believe that the

thesis of "fuel savings of 15-25%" - and it is a myth or fraud.

When I meet these sites - I make a detailed technical analysis of all

the declarations and documents and give the technical justification

that it is a lie. Andrew Ruban |

||||||||||||||||||||||||||||||||||||||

|

For what we take your money

:

1. The correct

calculation of power supply circuit boilers or furnaces. |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

| Additional

information |

|||

| full

version on the www.afuelsystems.com |

|||

|

|

home

page |

|

|