Some examples

TRGA tests and tests of fuel in industrial boilers, furnaces,

stand, oil refineries, locomotive and marine diesel engines, laboratories

and of course under long industrial use.

it - only a small part of photos and documents that are available

to us. it is only middlecover installed equipment whose owners

have sent us photos, reports, reviews and test results

|

|

|

|

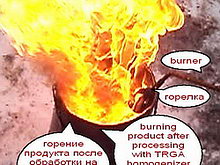

Russia,

Plesetsk, 2013.

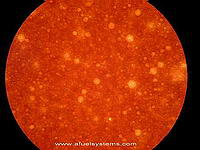

Treatment sludge from open storage. Changes in

the quality of sludge after treatment homogenizer TRGA. Burning

before and after, movies.

|

|

|

|

| Russia,

Habarovsk, 2013. Laboratory of Railways of the Russian Federation,

the official conclusion about changing the quality of fuel oil

after processing in a homogenizer TRGA. |

|

|

|

| Slovenia,

Ljubljana, 2013. Laboratory PETROL Slovenia, the official conclusion

about changing the quality of residual fuel RME-180 after processing

by a homogenizer TRGA. Analyses made by 7-15 days after treatment. |

|

| |

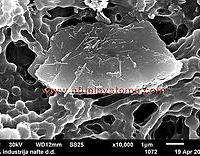

Croatia,

Zagreb, 2013. Laboratory of INA, the official conclusion about

changing the quality of residual fuel after processing in a homogenizer

TRGA.

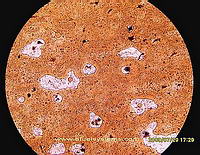

Comparative electronic pictures with magnification of 500 - 10

000 times and the findings of the lower solids and the nature

and quantity of the remaining particles. |

|

| |

| Croatia,

2013,

Rijeka. Shipboard fuel, improving the of properties results -

viscosity reduction - 15% reduction in carbon residue - 40%, the

official results. Analyses made by 1-2 days after preparation

of the samples concern INA Croatia. |

|

| |

Belgium,

Ostend 2012, testing of the system preparation ship ( marine )

fuel. The second test of the reliability and effect. Fuel type

- shipboard fuel IFO180. Full description.

The result - the ship's fuel savings of 4%, lower emissions, lower

the viscosity of the treated fuel, termination of emission fuel

in sludge reservoir when fuel passing through the separator. Report. |

|

| |

| Belgium,

Ostend, 2011, testing of the system of preparation of ship ( marine

) fuel. The first tests for reliability and effect. Fuel type

- shipboard fuel IFO180.

The result - reducing harmful emissions, reducing

the viscosity of the treated fuel, trouble-free reliable work

for 10 months.

|

|

| |

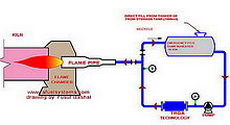

Turkey,

in 2011. Cement plant. Disposal of bilge water (flushing water

from ships) .....

Photo

1 . |

|

| |

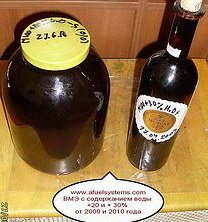

Ukraine,

Cherkassy, 2011, a study of water-oil-water emulsions - black

oil + water ( up to 20% of water), emulsion stability 3 years.

Emulsion samples were stored in the office and in the garage.

Fuel type - Heavy black oil mazout M-100.

Photo. |

|

| |

Guinea

Alumina Plant, 2 months of testsworks from January 2011. Fuel

type - analog M100 fuel oil, heavy fuel oil slurry. Result - 4%

fuel savings, reduction of carbon deposits on the heat exchangers,

reduction of atomizers clogging.

Then another device at the same company in 2011.

Photo1.

Photo_2.

Photo_3. |

|

| |

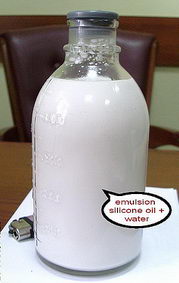

Ukraine,

Cherkassy, 2011. Research how to receive the silicone emulsion

with the addition and dispersion of high viscosity additive. According

this results installation was built in St. Petersburg.

The type of liquid - water + silicone emulsion with high viscosity

additive.

Photo. |

|

| |

Ukraine,

Cherkassy, 2011. Investigation of the influence of the new homogenizer

TRGA on the quality of mixing of additives to the fuel. Comparative

tests. Analysis of the results. A substantial change in the minimum

temperature filterability and freezing point by using a homogenizer

TRGA.

Photo.

Film - start

of the diesel engine at "-18" with the summer diesel

fuel. |

|

| |

Ukraine,

Cherkassy, 2011. Investigation degree of impact on the homogenizer

TRGA viscous fuel oil for example, a suspension of oil and mineral

additives. Liquid grinding, crushing and dissolving the solid

and granular additives in the oil with a homogenizer TRGA, creation

of of composite mixtures.

Photo. |

|

| |

Estonia,

Tallinn, 2011.Tehnichesky University, bench tests on a special

italian stand (5. KW, 4-cylinder, hydraulic brake, measuring equipment),

to investigate the specific consumption of diesel fuel. Result

- power increase 10%-12% savings.

Fantastic of course, but certified laboratory and the results

are similar to the tests

in Ukraine in Krivoy Rog.

Testing

and reasoning .. |

|

| |

|

| |

Russia,

Nizhny Novgorod, 2010, Installs our first industrial unit for

manufacturing of winter diesel fuel from a summer in the flow

and without pre-heating fuel. Review posted 8 months after the

start of works. Then there were many such devices. But it was

the first and escalate into a separate

direction.

Type of fuel - diesel fuel. Review.

Installation

in Belgorod Russia. |

|

| |

Ukraine,

Cherkassy, 2010, the study the level of exposure by homogenizer

TRGA on a fuel with example of processing of coal-water emulsion.

Type of fuel - coal-water emulsion. Photo. |

|

| |

Guinea

Alumina Plant, 2 months tests, is working from September 2010.

Fuel type - heavy fuel oil, heavy slurry fuel. Result - 4% fuel

savings, reduction of carbon deposits on the heat exchangers.

Full

test . Report.

This is the most thorough tests that have ever held with homogenizer

TRGA in a real industrial operation for a long time and repeatedly.

Then another one device at the same company in 2011.Test.

Photo.

Then another one on an aluminum plant in Siberia

2010 . |

|

| |

Turkey.

Denizli, 2010, possibilities of increasing the yield of light

fractions from crude oil, which was pre-treated by homogenizer

TRGA. The resulting increase in light fractions was 2.65%, diesel

5.6% , it was the first tests ... they are open.

Then there were tested in Mariupol (+3.5% - but they said "a

little"), Kremenchug (oil refineries, +2.8% - but they said

"fi" ...), Moscow (3.5-6.7% but did not negotiated a

price of the project).

After that, this direction was temporarily frozen, and the results

are not published.

Fuel Type - Crude oil and oil mixture. Comparative

Tables |

|

| |

Ukraine,

Cherkassy, 2010. For their own needs was assembled simple homemade

comparative viscometer for $ 30. This design became popular and

we were able to assess the changes in viscosity before and after

treatment of fuel oil on the module TRGA, has been very interesting

...

Fuel Type - heating fuel, fuel black oil.

Photo. |

|

| |

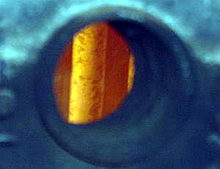

Ukraine,

Kremenchug, 2010. Installing the homogenizer at manufactruing

of multicomponent fuel mixtures, water fuel oil and so on and

so forth ...

Feature - an open area, round the clock, heavy black oil with

a high content of solids, lowest filtration at the input. The

guarantee was 4 months. Client allowed to make these photos after

16 months of exploitation (20/12/10) on May 2013 homogenizer TRGA

still works ...

Type of fuel - black oil, light oil sludge, waste, multi-blended

fuels oiled water ... Photo. |

|

| |

Ukraine,

Cherkassy, 2010. Trying partial dewaxing diese fuell. The scheme

works but for industrial use yet not necessary. Later, we'll go

the other way.

Type of fuel - diesel engine fuel. Photo.

|

|

| |

Ukraine,

Zaporozhye region, 2010. JSC "Zaporozhye iron ore plant."

Works to this day. The results - the successful burning of high-viscosity

oil. Increase stress and decrease fuel freezing point in winter,

reduction of atomizers clogging.

Fuel type - watered black oil M 100. Report. |

|

| |

Ukraine,

Mariupol, 2009. Mariupol trading port. Works till today, report.

Results - successful combustion recycle watered fuel mixture with

a water content of 20%. Watered oil sludge in the port. Bilge

water.

Fuel Type - a mixture of fuel oil and bilge water - fire incineration

recycling.

Paper presented at the international conference. |

|

| |

| Ukraine,

Kiev, 2009. The Fourth All-Ukrainian exhibition of energy saving

technologies.

In the category "Best Implemented Project

on energy saving in Ukraine" - the TRGA

device to save fuel oil won first

place.

|

|

| |

Ukraine,

Kiev, 2009. The object of the Ministry of Defense of Ukraine Makarov-1.

Working. (May 2013). Results - Successful watered fuel oil incineration.

Increase flow, reduction of atomizers clogging. Fuel does not

freeze in winter. Economy fuel. Report. In 2011 tested - boiler

(30 years of operation) works almost like new.

Fuel type - watered heavy fuel oil and fuel oil mixture, multi-blended

fuels. |

|

| |

Ukraine,

Cherkassy, 2009, after two years of sorting different options

picked "stand" for studying the completeness of combustion

of diesel fuel after hydrodynamic treatment. Stand comparison,

cheap and indicative, cost $ 30.

The stand allows you to compare the completeness and the temperature

of the combustion of diesel fuel, estimate the time after which

the treated diesel fuel recombined partially or completely. Everyone

was smiling. No one is denied.

Type of fuel - diesel fuel. Photo

1,

3,

4. |

|

| |

Ukraine,

Cherkassy, 2009, after 2 attempts assembled the stand to study

diesel economy on the diesel engine after the hydrodynamic treatment.

Precision our stand - is 2 times higher than the accuracy of the

diesel test stand on plant. Malyshev, Kharkov, cost $ 1,500.

Type of fuel - diesel fuel.Photo |

|

| |

Serbia,

Sremska Mitrovica, 2009, the municipal enterprise "Pannonian

power chains," tests by "Nikola Tesla Laboratory"

on environmental parameters.

Fuel type - black oil M 100. Photo.

Report

on the Environment. |

|

|

|

Belarus,

2010, tests to determine power, fuel-economic indicators and the

opacity of exhaust gases of the diesel engine when working on

diesel fuel with additive BPI. Mixing of fuel with a biocatalyst

carried by a homogenizer TRGA. The result - saving in fuel consumption

2.5%. Potentiation of the additive in the fuel

Type of fuel - diesel engine fuel. Report. |

|

| |

Ukraine,

Kharkov, 2009. Plant. Malyshev (production of tanks and armored

personnel carriers). Rheostat winter tests to cut down on diesel

engines (Booth, 2 cylinder wear 0%), is it possible to reduce

the specific consumption of diesel fuel and smoke reduction. Duration

6 hours. Photos - banned. The report is available only to professionals.

Calculated result - reduction of specific consumption by 1%. Official

Report, 62 pages. For all history of this enterprise it was the

only one report which says that the engineers of this plant. "can

not explain the increase in the level of CO2 (+19%) and NOx (+20%)

with the same amount of diesel fuel burnt in the engine."

My

remarks on the results here. The program of cooperation with

the iron ore quarry was abandoned.

The official conclusion of the customer (the

quarry for mining of iron ore) of own previous rheostat tests

sheet

1 and sheet

2 - was neither withdrawn nor disproved.

Type

of fuel - diesel engine fuel.

Saving diesel fuel 10% fantastic or reality ? |

|

| |

Turkey

Denizli, 2009, research of homogenization of ship fuel IFO-180

without water and water fuel oil emulsion water - black oil IFO-180.

Fuel type - shipboard fuel IFO-180. Photo. |

|

| |

Ukraine,

Cherkassy, 2009, research of water-oil emulsion black oil and

water.

Fuel type - Heavy black oil mazout M-100, multi-blended fuels.

Photo. |

|

| |

Ukraine,

Cherkassy, 2009, research of homogenization of black oil mazout

M-100.

Fuel type - Heavy black oil mazout M-100.

Photo. |

|

| |

Ukraine,

Cherkassy, 2009, a research of homogenization coal tar pitch.

Type of fuel - coal tar pitch. Photo

2,

3.

Report. |

|

| |

Russian

Federation,

Samara, 2009, Research of properties of multi-fuel mixtures that

are obtained by using a homogenizer TRGA.

Fuel type - multi-blended fuels. Отчет. |

|

| |

Ukraine,

Cherkassy plant of building materials, 2009. Works to this day.

The result - the successful burning coke fuel increase steam output

of the boiler, reducing drying time of bricks by 40%.

Film-1. Film-2.

Type of fuel - fuel coke with water. |

|

|

|

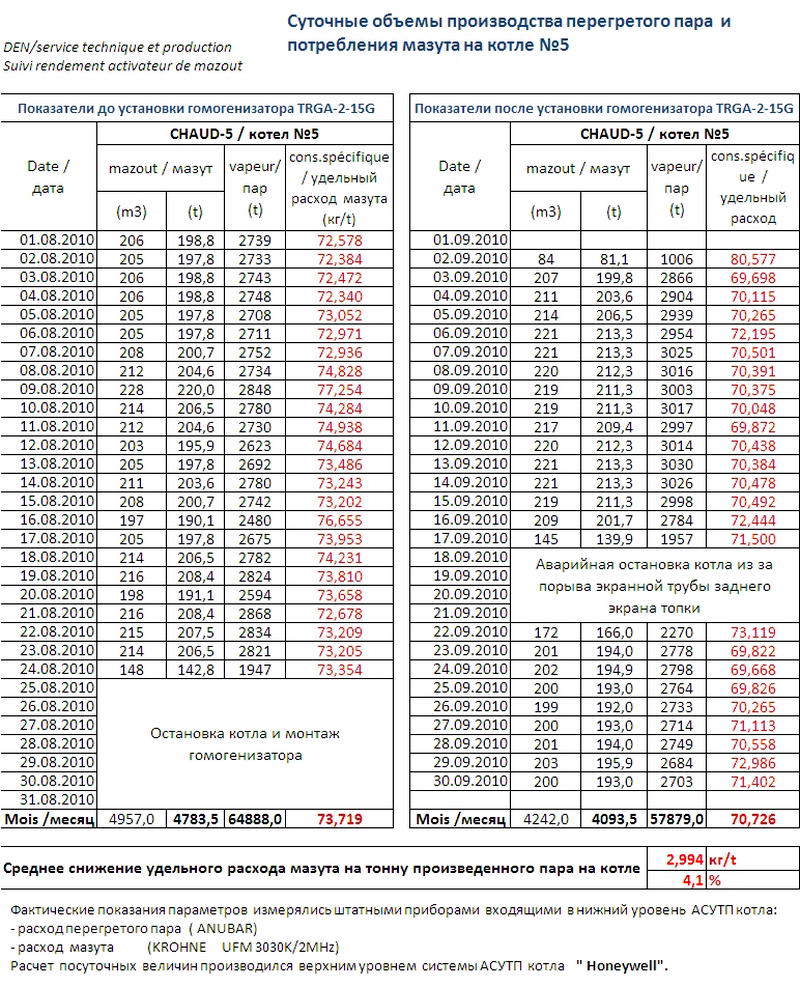

Ukraine,

Dnepropetrovsk, OAO "Dneproshina," 2009, set 2 activators

and 1 homogenizer TRGA for preparation of fuel, the report is

received after 6 work months. Exploitation of 24 months. The result

- the successful burning coke fuel.

Type of fuel - fuel coke. Report |

|

| |

Belarus,

Brest, in 2009, the municipal enterprise "Brest boiler"

, the successful burning 750 tons old black oil with water content

of 54%. Report. Working 2 year. The result - a successful burning

watered mazout.

Fuel type - watered mazout. Report. |

|

| |

Ukraine,

Krivoy Rog, "Northern Mining," 2008. Rheostat

winter tests on the locomotive (wear 60%), is it possible

to reduce the specific consumption of diesel fuel and smoke reduction.

Duration 3.5 hours.

Preliminary results - reducing specific consumption for 5.54%,

a decrease of smoke. Report.

Photo.

The final result - the reduction of specific consumption by 14%.

Report.

Letter to increase the power

of the diesel generator at 7.7% Type of fuel - diesel engine

fuel. |

|

| |

Ukraine,

Krivoy Rog, "Northern Mining," 2008. Rheostat flight

tests on the locomotive (wear 60%), is it possible to reduce the

specific consumption of diesel fuel and smoke reduction. Duration

8 hours. The result - an increase in efficiency Engine 2% reduction

in specific consumption at 10.58%, a two-fold reduction in smoke.

Type of fuel - diesel engine fuel. Report.

Photo. |

|

|

|

Serbia,

Sremska Mitrovica, 2008, the municipal enterprise "Pannonian

power chains," 12 months of exploitation, 2 industrial tests

them. Nikola Tesla's laboratary report. 6 months of operation.

Results Summary - 2.6% fuel savings, reduced NOx, SO2, CO.

Fuel type - Heavy black oil mazout M-100. Report

fuel economy. Report

ecology . |

|

| |

Ukraine,

Cherkassy, 2008, the creation of the first examples of water-fuel

emulsions. May, 2013 - all samples hydrogen fuel oil emulsion

having, water content is 5, 10, 15, 20%, all samples are kept

stable and no separation.

Fuel type - Heavy black oil mazout M-100.

First

photo 2008. Photo

2011 . |

|

|

|

Croatia,

Rijeka, 2008, the municipal enterprise "Energy", 11

months of exploitation, 2 months of tests. Results Summary - 3.7%

fuel savings, reduced CO - 40%. Test. Tests conducted Polytechnic

Institute Rijeka, Croatia.

Fuel Type - stove fuel. Light mazout. Report.

|

|

|

objective

results

Direct fuel economywhen installing TRGA-2-15G = 4%

|

|

|

All

photos were taken on objects when installed activators and fuel

homogenizers series TRGA-3G.

Authors of photos. Sergei Shlyaga, Yusuf Basha, Constantine Animitsa,

Andrey Ruban.

other

photo

|

|